隧道式烘干线的使用特点

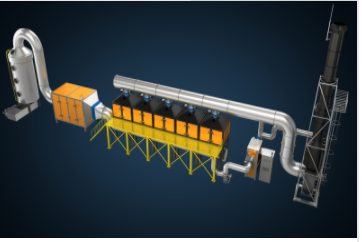

Tunnel drying line the equipment is a tunnel type chain mesh belt through type drying equipment, using a special chain transmission to transport workpieces, with drying, drying and other functions of novel continuous drying equipment. The workpiece is manually placed on the transmission chain mesh belt and discharged after drying in turn. The mist in the upper hood is extracted by the suction fan and discharged to the main exhaust pipe. The machine has the advantages of full function, reasonable structure, convenient operation and good drying effect, which is of great significance for mass drying, improving the working environment and improving the quality. The fuselage structure adopts sealed type, with beautiful appearance and convenient equipment disassembly and maintenance.

1、 上料/下料区:

1. Loading / unloading area:

在进料口处设置一条网带露置于机体外,构成上料区,过完上料传动进入烘干区经过热风循环进行烘干,后面装置工业风扇对工件进行冷却,在出料口处设置一条网带露于机体外构成下料区。并使网带传送链形成一个完整的循环链。网带距地面高0.8m,方便操作人员操作。

A mesh belt is set at the feeding port and exposed outside the machine body to form a feeding area. After feeding, the belt is driven into the drying area and dried by hot air circulation. An industrial fan is installed at the back to cool the workpiece. A mesh belt is set at the discharging port and exposed outside the machine body to form a blanking area. And make the belt conveyor chain form a complete cycle chain. The net belt is 0.8m high from the ground, which is convenient for operators.

2、 烘干区:

2. Drying area:

设备设置了烘干区,加热方式采用电(石英管)加热式加热(如有需要也可设置煤气生物质颗粒加热系统),温度常温—300℃可调。设置保温、排风、温度、抽雾系统控制等系统,使设备恒温可调。

The drying area is set in the equipment, and the heating mode is electric (quartz tube) heating (if necessary, gas biomass particle heating system can be set), and the temperature is adjustable from normal temperature to 300 ℃. The control system of heat preservation, exhaust, temperature and mist extraction system is set to make the constant temperature of the equipment adjustable.

当工件在上料区进入烘干区后,以0.5-3m/min的速度行进,烘干,将工件以设定的温度进行烘干,下料。在烘干炉上设置运风、排风系统,使工件在系统内均匀受热,并将废气水雾抽出,避免污染车间环境。

When the workpiece enters the drying area in the feeding area, it moves at the speed of 0.5-3m / min to dry, and then the workpiece is dried at the set temperature for blanking. The air conveying and exhaust system is set on the drying furnace to make the workpiece evenly heated in the system and extract the waste gas and water mist to avoid polluting the workshop environment.

3、 网带输送链传动系统:

3. Mesh belt conveyor chain drive system:

系统传动为封闭循环式网带链条自动传动,其长度约为26m;线体轨道为“U”形轨道,以法兰片/螺丝连接,运行稳定可靠。设动力装置、张紧装置、防滑胶条、被动齿轮、接油杯、挂钩等,运行稳定,速度0.5-3m/min可调。

The transmission system is a closed loop mesh belt chain automatic transmission with a length of about 26m; The line track is a "U" shaped track, which is connected by flange / screw, so the operation is stable and reliable. It is equipped with power device, tension device, anti-skid rubber strip, passive gear, oil cup, hook, etc., with stable operation and adjustable speed of 0.5-3m / min.

今日越华润华的精彩内容就给大家分享到这了,更多的精彩内容请点击我们的网站www.yuehuarunhua.comm留言,或者直接拨打电话询问,我们会有专门的人员为您服务.

Today, we will share the wonderful content of Yuehua Runhua. For more wonderful content, please click our website http://www.yuehuarunhua.com Leave a message, or call directly, we will have special staff to serve you

下一篇:布袋除尘设备脉冲除尘器的知识